A Solution for Less Intrusive Foundational Work: Helical Piles.

While the technology has been around for some time, the popularity of helical pile foundation systems on the Gulf Coast has been rapidly increasing due to its ability to do more within restricted environments.

The helical pile foundation system has been a common practice in many northern states for years, but local owners are discovering that it is suited for Louisiana job sites as well. The industrial market, in particular, benefits from using this system.

Continue reading to learn more about helical pile foundations and how GROUP Contractors is using them to benefit clients!

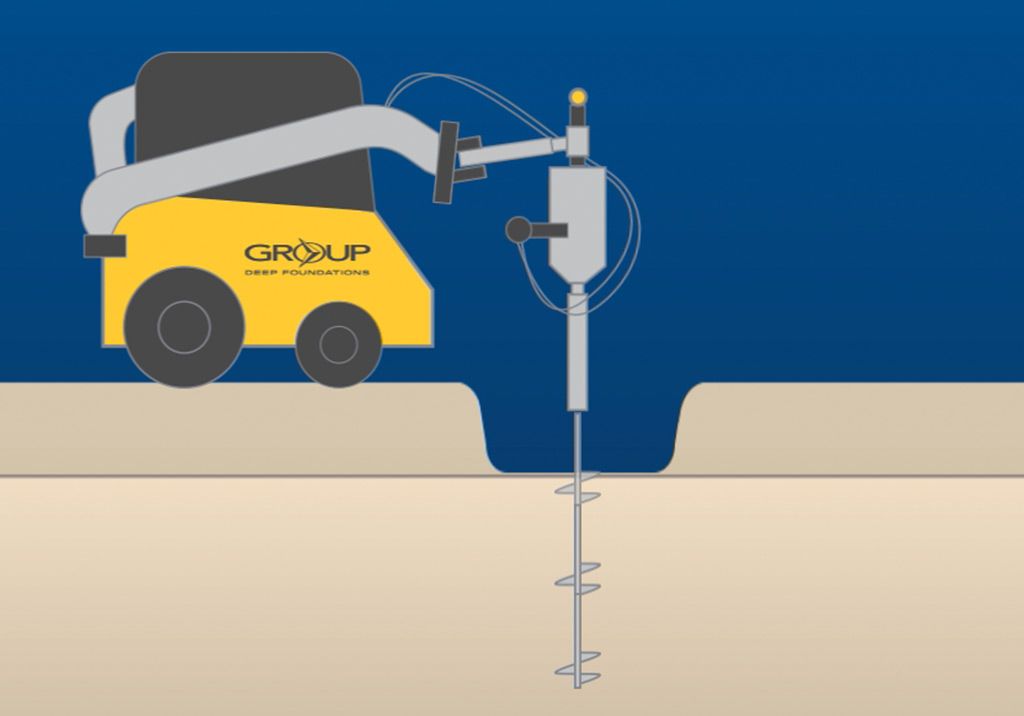

The helical pile foundation system is suitable for just about any situation and offers more forgiving installation methods that have less of an impact on the surrounding environment. Available in a variety of diameters, helical piles are not as messy as auger cast piles or drill shafts. They are wound or corkscrewed into the ground by a skid-steer loader or excavator, outfitted with a rotary hydraulic powerhead and special drive attachments that connect the pile to the machine.

“The unique foundation system is ideal for energy, industrial and commercial applications as it offers reduced construction time, minimal excavation and spoil removal, and no harmful vibrations during installation.” –Justin Vicknair, GROUP Contractors Superintendent

This system also helps to cut installation times and costs compared to conventional drilled shafts as they are “screwed” into the ground and create less soil displacement, so there is no need to transport excess soil from the site. This saves on transportation costs and reduces the carbon footprint of the project.

There is no such thing as a bad application for helical piles. They can be used in just about every soil condition, and they are ideal for projects that are time-sensitive or in difficult-to-reach places.

GROUP Contractors is constantly finding new uses for this technology on the Gulf Coast, whether for a chemical plant in Texas needing support for a pipe in a canal or a stadium expansion needing foundations near a stand of protected live oak trees. The possibilities with helical piles are seemingly endless, and they are proving to be a valuable asset for ensuring safe and on-time delivery of projects for our valued clients.

[ssba-buttons]

A Solution for Less Intrusive Foundational Work: Helical Piles.

While the technology has been around for some time, the popularity of helical pile foundation systems on the Gulf Coast has been rapidly increasing due to its ability to do more within restricted environments.

The helical pile foundation system has been a common practice in many northern states for years, but local owners are discovering that it is suited for Louisiana job sites as well. The industrial market, in particular, benefits from using this system.

Continue reading to learn more about helical pile foundations and how GROUP Contractors is using them to benefit clients!

The helical pile foundation system is suitable for just about any situation and offers more forgiving installation methods that have less of an impact on the surrounding environment. Available in a variety of diameters, helical piles are not as messy as auger cast piles or drill shafts. They are wound or corkscrewed into the ground by a skid-steer loader or excavator, outfitted with a rotary hydraulic powerhead and special drive attachments that connect the pile to the machine.

“The unique foundation system is ideal for energy, industrial and commercial applications as it offers reduced construction time, minimal excavation and spoil removal, and no harmful vibrations during installation.” –Justin Vicknair, GROUP Contractors Superintendent

This system also helps to cut installation times and costs compared to conventional drilled shafts as they are “screwed” into the ground and create less soil displacement, so there is no need to transport excess soil from the site. This saves on transportation costs and reduces the carbon footprint of the project.

There is no such thing as a bad application for helical piles. They can be used in just about every soil condition, and they are ideal for projects that are time-sensitive or in difficult-to-reach places.

GROUP Contractors is constantly finding new uses for this technology on the Gulf Coast, whether for a chemical plant in Texas needing support for a pipe in a canal or a stadium expansion needing foundations near a stand of protected live oak trees. The possibilities with helical piles are seemingly endless, and they are proving to be a valuable asset for ensuring safe and on-time delivery of projects for our valued clients.